CANTILEVER RACKING EXTRAS

CANTILEVER RACKING EXTRAS

All of Wickens Cantilever Racks are bespoke, designed and manufactured to suit customers’ particular requirements. Depending on the product type and storage application, racking extras might be recommended to ensure that the racking system is suitable, used efficiently and safely.

Here are some of the most popular Cantilever Rack extras, but other options are available depending on requirements.

ARM END CAPS

As standard, Cantilever Racking arms are supplied with either black flat arm end caps or yellow domed arm end caps depending on the arm section, which is based on the arm length and the load. Arm end caps are only compatible with box section arms.

HEAD GUARDS

Optional protective foam head guards are compatible with universal beam arms only and are normally applied to one level of arms at head height.

WELDED ARM END STOPS & RETAINING PINS

Welded End Stops and removable Retaining Pins prevent tubular products from rolling off Cantilever Racking arms. Both types of arm end stops vary in height to suit the application.

TYRE GUARDS

Cantilever Rack bases could be supplied with tyre guards to prevent damage to forklift tyres. Welded End Stops and removable Retaining Pins prevent tubular products from rolling off Cantilever Racking arms. Both types of arm end stops vary in height to suit the application.

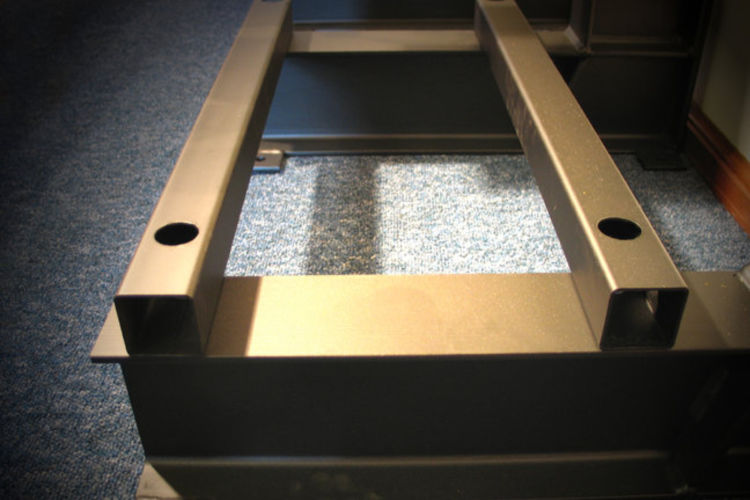

LINTEL RAILS & ARM TIES

Lintel Rails are most commonly used on the base level of cantilever racks and are often referred as base rails. Both lintel rails and arm ties allow storing different length products on the same rack or serve as a support for pallets or decking.

DECKING

Cantilever Racking can be supplied with timber or steel mesh decking. Decks form a continuous open-front shelving unit, allowing storage of various length products at any location of a rack. Timber decking is generally more cost-effective; however galvanised mesh decks are more suitable for external applications.

SPINDLE HOLDERS ON ARMS

An option of spindle holders on cantilever arms is available on request. Welded to Cantilever Rack arms, spindle holders are specially fabricated to suit specific spindle sizes and storage application. Alternatively, other bespoke storage solutions might be recommended depending on the requirements.

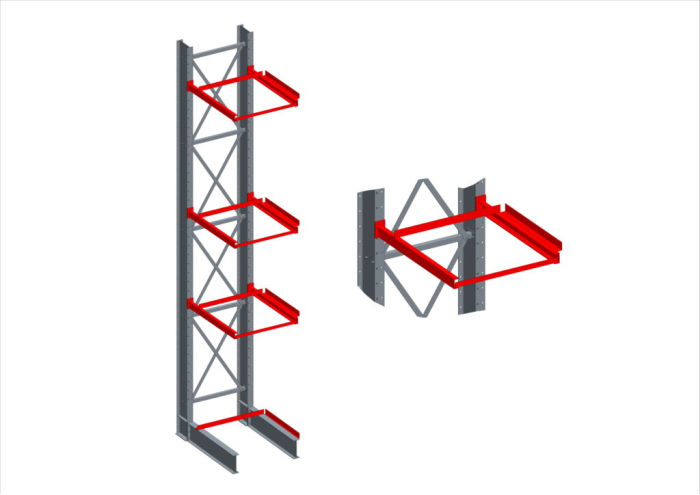

P&D STATIONS

Wickens design and manufacture Cantilever P&D (Pick Up & Deposit) stations that are used at the end of the racking aisles to improve the operation time and logistics in a warehouse. P&D Cantilever Racks are fitted with arm ties, supplied with pallet guides on arms and pallet back stops to ensure efficient loading of the rack in a busy warehousing environment.

ROOF CANOPIES & RAINWATER GOODS

Racks could be fitted with roof canopies and rainwater goods. Learn more about Cantilever Racking with Canopies here.

FULLY ENCLOSED RACKING SYSTEMS

Alternatively, a fully enclosed racking system with a roof canopy, side cladding and optional doors or curtains could be supplied for complete protection from the elements and additional security to stock.

Depending on your storage requirements, Wickens can design a bespoke solution to suit your products. If your requirements are more complex, a site survey might be conducted to ensure that the most appropriate and cost-effective racking system is offered to you